PVC-Coated Fabrics Suited for Your Building Project

Most structure fabric materials are durable and able to work for many types of buildings when manufactured, inspected and installed correctly. At a glance, polyethylene products have many similarities to PVC products, but PVC fabrics offer some key advantages.

| PVC Coated Fabrics | Polyethylene Fabrics | |

| Tensile Strip |

Superior | Poor |

| Tensile Tear | Superior | Poor |

| Tensile Trap | Superior | Poor |

| Tensile Burst | Superior | Poor |

| Flammability | Inherently Flame Resistant |

Flammable Unless Treated |

| Cold Crack | Resistant Beyond -40C (-40F) |

Up to -40C (-40F) |

| Color Availability | All Colors Available | Limited to Large Scale Only |

| Fold Resistance | Multiple Folds / Deployment |

Single Deployment Only |

| Repairability | Multiple; Easily Repaired |

Single; Difficult to Repair |

| Base Fabric Structures |

Both Woven and Knitted |

Woven Only |

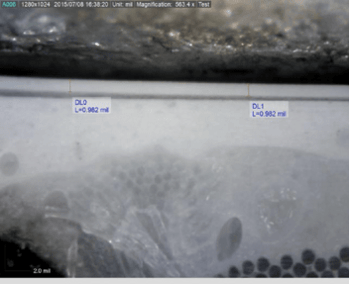

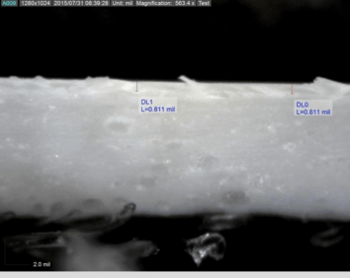

Tedlar & Non-Tedlar Surfaces

Cross-sectional Views of Tedlar vs. Non Tedlar Architectural Fabrics.

| Tedlar Film Coated Shelter-Rite Fabric Structure | Lacquer Coated Non Shelter-Rite Fabric Structure |

|

|

|

|